Knowledge Center

- Downloads

- Technical Newsletter

- Recommended Guidelines and References

- Specifications

- Technical Papers

- Tools and Calculators

- Training

- Articles, Tips and Requirements

- An Integrated Approach to Manage Vibration Risks

- Design Requirements for Reciprocating Compressors

- Evaluating Compressor Operating Risks

- Five simple methods to check reciprocating compressor performance

- Important Differences in Pulsation Software

- Liquid Pumping Systems (Including Liquid Pipelines)

- Noise Regulations Around the World

- Noise Risks in the Gas Industry

- Performance Monitoring Examples

- Pipe Support Stiffness, GMRC Project

- Piping Vibration Design Considerations

- Piping Vibration Examples

- Structural Vibration and Ways to Avoid It

- Tips for a Successful Project (Vibration Control)

- Transient Conditions on Small-Bore Piping

- Vendor Requirements for Piping Vibration & Integrity Assessment

- Vibration-induced fatigue (whitepaper)

- Vibration Issues Affecting Gas Compressor Facilities

- Ask the expert

Vibration Issues Affecting Gas Compressor Facilities

Because the following vibration issues are often linked together, Wood betoften works directly for the owner. This ensures a much better solution – both technically and financially.

Contents [ hide ]

1 Compressor Piping System

Mechanical stiffness and dynamic forces must be controlled or managed effectively to avoid resonance and excessive vibration. The issues vary by compressor:

Reciprocating Compressors

-

For larger compressors (e.g., over 500 HP or 360 KW), a Pulsation and Mechanical Analysis is generally required to control pulsation forces and avoid resonance for the compressor frame, bottles, piping, and process vessels.

- A Torsional Vibration Analysis is also recommended to properly design the torsional system and avoid crankshaft and coupling failures.

- Depending on the application, other design considerations may be recommended.

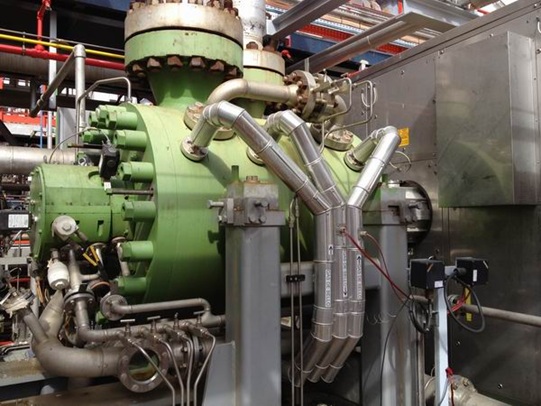

- Reciprocating Compressors

|

|

|

Centrifugal Compressors

- Surge Control Dynamic Analysis is required to properly design the piping system, valves, recycle lines and other components of the system to prevent violent vibration associated with compressor surge.

- Lateral vibration of the compressor shaft is addressed in a Lateral Vibration Analysis. When OEMs conduct a lateral analysis it is customary for Wood to audit or review the lateral design.

- Centrifugal Compressors

Screw Compressors

- A Pulsation and Mechanical Analysis is required for larger compressors (e.g., over 500 HP or 360 KW). Pressure pulsations at pocket passing frequency can create high vibration leading to pipe failures, instrumentation failures, and excessive noise. Mechanical resonance can bring about the same problems even if pressure pulsations are controlled.

- A Pipe Stress Analysis is required for the discharge piping. A stiff pipe layout and support design is required to control vibration, however this may result in high pipe stress and equipment loads.

- Screw Compressors

2 Small-Bore Connections

Small-bore connections (SBC), also called branch connections, are the most common piping failure and should be evaluated and tested. A Small-Bore Connections Assessment that includes shop and field testing is strongly recommended to avoid piping integrity risks.

3 Station Piping (including off-skid)

- A Pipe Stress Analysis predicts stresses in piping and loads resulting from changes in temperature, weight, pipe and valves, pressure, wind load, and seismic loads. This study is typically required for piping that experiences high temperature fluctuations, or for long pipe runs such as hot piping between the compressor discharge and heat exchangers.

- When multiple compressors are installed at a station, the pulsation analysis must include compressor interaction between reciprocating compressors, or between reciprocating and centrifugal compressors.

- Flow-induced vibration, or vortex shedding, is vibration that results from flow and pressure fluctuations due to a sudden geometry change or physical disruption in a centrifugal compressor system’s piping . The most common source of flow-induced vibration is vortex shedding resulting from flow past dead leg branches.

- Pipe Stress Analysis

- Flow-Induced Vibration (FIV) Analysis

- Piping Vibration and Integrity Assessment

4 Foundation

|

|

|

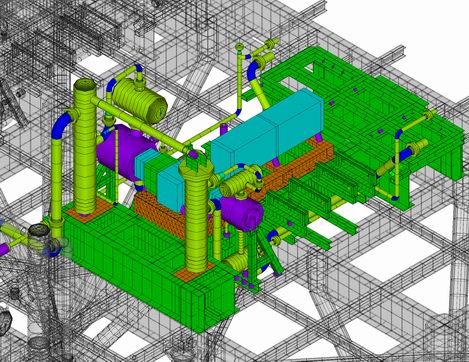

A dynamically stiff base or foundation is needed to support forces in the machine and piping. For land based applications, foundation refers to concrete block, pile, or gravel pad foundations. For offshore applications, foundation refers to platform decks and FPSO topside modules. Best practices in foundation design require a Foundation Design and Dynamic Analysis to avoid excessive vibration of the skid and foundation. The following are some best practices:

- A Skid Design and Analysis includes the compressor finite element (FE) model to ensure dynamic forces are accurately transferred to the skid.

- A reciprocating compressor skid dynamic response is strongly dependent on the foundation stiffness. This is particularly true for pile foundations and offshore applications. It is strongly recommended that a foundation/structural dynamic study is performed, and coordinated with the compressor/pump mechanical analysis. This ensures the foundation structure, skid, and compressor FE models are integrated together to ensure accurate results and better recommendations to avoid excessive vibration.

- Adding concrete to selective locations in the skid generally reduces vibration of the compressor and other equipment on the package. Anti-vibration mounts (AVMs) can be designed for reciprocating compressors, but require more comprehensive analysis and typically require larger, and more costly, skid structures.

- The dynamic design of concrete foundations must include soil dynamic properties measured from site geotechnical testing or supplied by geotechnical consultants with local knowledge. Specialized analysis techniques are required to accurately simulate soil dynamic responses.

- Installation techniques are critical. These ensure correct mounting of the compressor to the skid and foundation, including bolting and grouting.

Free webinar

Learn how to select and design vibration control solutions that work – using real-world data and case studies. Register now