Piping System

Vibration and stress

Vibration-induced fatigue, pipe stress, transient events and small-bore connections are high-risk areas requiring Wood's engineering support.

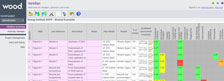

New piping vibration screening software: Veridian™

Identify high-risk locations and track anomalies with our new, complimentary software tool. Web-based, secure, confidential.

Veridian overview

Get started with a free account

Download the Veridian capability sheet (PDF)

Piping vibration risks and design considerations

New vibration requirements for blowdown systems: Acoustic Fatigue

Overview: Static vs dynamic design requirements (pdf)

Summary: Piping vibration risk management (pdf)

Why include vibration-induced fatigue in my Asset Integrity Management (AIM) program? READ MORE (PDF)

Webinar: Vibration problem solving – common solutions

Learn about the pros and cons of common (and some unconventional) vibration control solutions

View MoreWebinar: Introduction to piping vibration

Learn how to identify risks and prevent failures on main line piping

View MoreWebinar: Shake, rattle and grow I (2022 update)

.jpg)

Pipe stress and vibration design – new piping stress modeling techniques for more accurate designs

View MoreWebinar: Piping and tubing vibration anomaly mgmt

New methods to find and track vibration threats in small-bore piping and tubing

View MoreExamples of Piping Vibration (Video)

Small-bore and mainline piping vibration: a common integrity issue for owners.

View MoreAvoiding vibration-induced fatigue failure

How web tools enable effective piping vibration management

View MoreAcoustic Fatigue Assessment for Blowdown Systems

API Std 521 for pressure relief and blowdown valves

View MorePiping Vibration and Integrity Assessment

Piping vibration analysis per EI 2008 Guidelines for the avoidance of vibration-induced fatigue failure (AVIFF).

View MoreTroubleshooting, Root Cause Analysis (RCA)

Advanced vibration analysis including pulsation, resonance, stress and transients

View MoreAn Integrated Approach to Manage Vibration Risks

Easily avoid integrity risks that result from many different sources.

View MoreProducts

Wood’s line of anti-vibration products provide unique solutions to the most-challenging piping fatigue risks and vibration problems.

View MoreWebinar: Feeling the pulse

Reciprocating compressor system design: how to avoid pulsation pitfalls in suction and discharge piping systems

View MoreWebinar: Piping vibration control solutions

New standards and solutions for piping in vibratory service

View MoreWebinar: Shake, rattle and grow – part II

How to select the right pipe clamp to control vibration and allow thermal growth

View MoreWebinar: Shake, rattle and grow – part III

How to quantify performance of pipe supports for vibration service

View More

_Analysis_-_grid.jpg)

_Vibration_Analysis_-_grid.jpg)

_Analysis_-_grid.jpg)