Services

- Static Equipment & Structures (Piping Vibration & Fatigue)

- Acoustic Fatigue Assessment for Blowdown Systems

- Acoustic-Induced Vibration (AIV) Analysis

- Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD)

- Flow-Induced Turbulence (FIT) Analysis

- Flow-Induced Vibration (FIV) Analysis

- Multiphase and Slug Flow Analysis

- Pipe Stress Analysis

- Piping Vibration and Integrity Assessment

- Review & Design Support Services

- Small-Bore Connections (SBC) Assessment

- Structural Vibration and Dynamic Design Analysis

- Subsea Piping Vibration

- Thermal Striping

- Tube Failure Analysis

- Veridian AM

- Veridian VS

- Vibration Inspection Program

- Water Hammer Analysis

- Machinery Analysis

- Bottle Sizing Service

- Compressor Package Engineering

- Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD)

- Foundation Design and Dynamic Analysis

- Fuel Gas Compressor Piping Transient Analysis

- Lateral Vibration Analysis

- Pipe Stress Analysis

- Pulsation & Mechanical Analysis: Reciprocating Compressor

- Pulsation & Mechanical Analysis: Reciprocating Pump

- Pulsation & Mechanical Analysis: Screw Compressor

- Pump RCF Analysis

- Review & Design Support Services

- Shell Transverse Acoustical (STA) Analysis

- Skid Design and Analysis

- Surge Control Design for Centrifugal Compressor Systems

- Torsional Vibration Analysis (TVA)

- Field Engineering & Troubleshooting

- Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD)

- Human Vibration

- Motion Amplification Vibration Analysis

- Noise Troubleshooting

- Performance Assessment (Thermodynamic)

- PostPro – field data processing and analysis

- Structural Vibration Troubleshooting

- Thermal Striping

- Troubleshooting, Root Cause Analysis (RCA)

- Veridian iDAC

- Vibration Inspection Program

Subsea Piping Vibration

For new and existing systems

Subsea systems are becoming more complex and are being designed for and operated at ever increasing water depths. One aspect that is often overlooked is the threat associated with vibration, which can lead to significant integrity and reliability issues.

Vibration is caused by a number of sources, including:

- External flow: tidal or current loading, leading to vortex-induced vibration (VIV)

- Internal flow: flow-induced vibration (FIV) including flow turbulence (FIT), multiphase and slugging, flow-induced pulsation (FLIP/singing flexibles and deadleg excitation)

- Mechanical excitation: residual imbalance and misalignment of subsea pumping and compression equipment

Wood’s vibration, dynamics and noise (VDN) group provides a comprehensive range of services to manage the threat of vibration-induced fatigue and associated reliability issues across the lifecycle of subsea equipment.

Contents [ hide ]

1 Why is subsea vibration an issue?

The risks from flow or process-induced vibration excitation of pipework are widely acknowledged in onshore process plant and offshore topsides facilities. Conversely, the vibration assessment of subsea pipework has historically been limited to external vortex-induced vibration (VIV) of riser systems and unsupported pipeline spans due to environmental loading. Existing integrity management guidelines for subsea systems do therefore not adequately address internal flow-induced vibration.

However, recent failures and associated reliability issues of subsea equipment, in part due to increased flow rates and increasing equipment complexity, have raised the risk profile of internal flow-induced vibration excitation and led, through an industry JIP, to the development of new guidelines which will be published in 2016 by the Energy Institute.

|

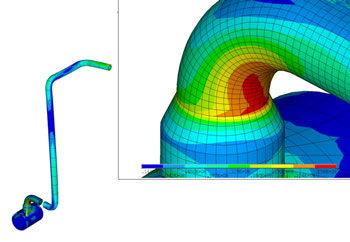

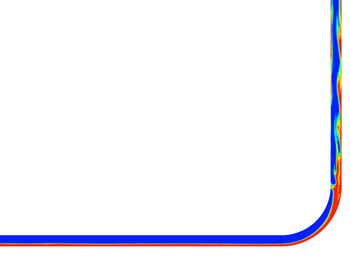

Dynamic stress analysis of an ROV intervention line |

|

CFD prediction of multiphase flow around a bend |

Examples include:

- Vibration-induced fatigue failure of piping on a subsea production manifold soon after start-up which resulted in the recovery of the manifold back to shore for repair.

- Severe high-frequency vibration of subsea equipment caused by a ‘singing riser’ which led to a reduction in gas export flowrates to allow safe operation until suitable vibration control measures were designed and deployed.

- Excessive low-frequency vibration of a rigid production jumper which resulted in an extended monitoring program to determine and hence minimize the fatigue damage accrual under certain operating conditions, followed by the deployment of vibration mitigation measures using an ROV.

2 Design

During the project design stage, Wood’s VDN service line can support the project through carrying out a range of technical services:

- High-level screening and risk assessments to identify potential issues across the anticipated range of process and operational conditions

- Input to design decisions to leverage ‘lessons lea rned’ from previous projects

- Detailed fatigue simulation for identified fatigue hot spots

- Identification and quantification of potential vibration control measures

3 Operations

During operations, VDN can support the asset team through:

- Assessment of the effect of changing process and operational parameters using risk assessment methods and detailed simulation (management of change)

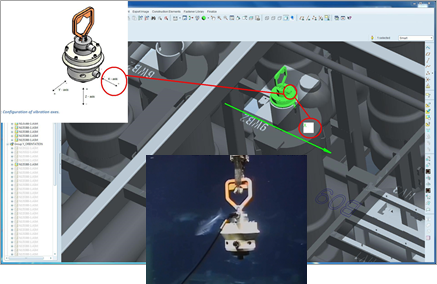

- Specification of monitoring requirements and survey implementation

- Analysis of subsea vibration measurement data and associated fatigue assessment

- Identification and quantification of potential vibration control measures

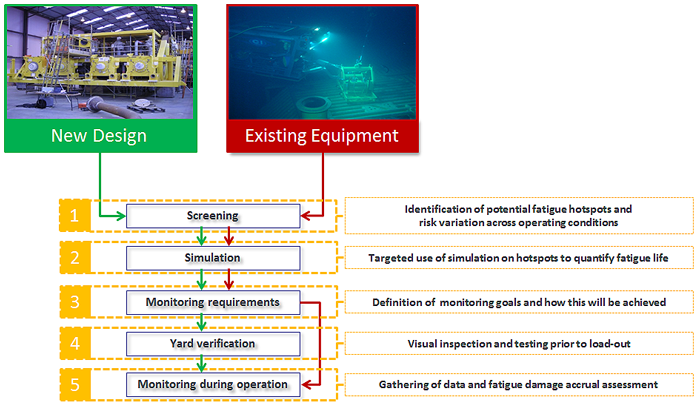

|

|

| Production manifold during construction | Subsea vibration monitoring on a manifold (image courtesy of ClampOn) |

4 Research and joint industry projects (JIPs)

Existing guidance on vibration in piping systems is aimed at topsides and onshore piping systems. Given the unique challenges with subsea systems, the need for separate guidance was identified. Development of this new subsea guideline was commissioned by the Energy Institute (EI).

Objectives:

- Identify good design practice and hence ensure a robust design

- Extend screening methodologies to include additional excitation mechanisms, and reduce conservatism in certain methods

- Provide additional guidance on detailed fatigue assessment approaches

- Provide guidance on subsea vibration monitoring methods, and the use of monitoring data

The key steps in the assessment process are shown below:

The new document is in final draft and expected to be published soon. The steering committee includes representatives from a number of operators including Shell, BP, Total and Chevron. The VDN service line is currently performing an assessment for a subsea tie-back to an existing installation.

4 Inquiries

For more details, or to discuss your specific subsea vibration integrity concerns, please email our dedicated subsea experts at info.vdn@woodplc.com.

5 Subsea Tiebacks 2016

The Wood Kenny Americas team exhibited at Subsea Tiebacks 2016 in San Antonio from 22-24 March. Rob Swindell, Vibration Engineering Lead and Technical Authority with vibration, dynamics and noise (BETA) was speaking about managing critical asset integrity through specialist engineering. If you have any questions about his presentation or asset integrity in your project, don't hesitate to contact Rob.

Related Services

- Piping Vibration and Integrity Assessment (Energy Institute Study, 2008, AVIFF)

- Pipe Stress Analysis

- Flow-Induced Turbulence (FIT) Analysis

- Flow-Induced Vibration (FIV) Analysis

Keywords

- Subsea vibration

- Vibration of subsea piping

- VIV

- Flow-induced vibrations of subsea piping

- FIV

- FIT

- FLIP

- Multiphase

- Subsea vibration screening

- Subsea piping integrity

Free webinar

Learn how to select and design vibration control solutions that work – using real-world data and case studies. Register now