Services

- Static Equipment & Structures (Piping Vibration & Fatigue)

- Acoustic Fatigue Assessment for Blowdown Systems

- Acoustic-Induced Vibration (AIV) Analysis

- Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD)

- Flow-Induced Turbulence (FIT) Analysis

- Flow-Induced Vibration (FIV) Analysis

- Multiphase and Slug Flow Analysis

- Pipe Stress Analysis

- Piping Vibration and Integrity Assessment

- Review & Design Support Services

- Small-Bore Connections (SBC) Assessment

- Structural Vibration and Dynamic Design Analysis

- Subsea Piping Vibration

- Thermal Striping

- Tube Failure Analysis

- Veridian AM

- Veridian VS

- Vibration Inspection Program

- Water Hammer Analysis

- Machinery Analysis

- Bottle Sizing Service

- Compressor Package Engineering

- Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD)

- Foundation Design and Dynamic Analysis

- Fuel Gas Compressor Piping Transient Analysis

- Lateral Vibration Analysis

- Pipe Stress Analysis

- Pulsation & Mechanical Analysis: Reciprocating Compressor

- Pulsation & Mechanical Analysis: Reciprocating Pump

- Pulsation & Mechanical Analysis: Screw Compressor

- Pump RCF Analysis

- Review & Design Support Services

- Shell Transverse Acoustical (STA) Analysis

- Skid Design and Analysis

- Surge Control Design for Centrifugal Compressor Systems

- Torsional Vibration Analysis (TVA)

- Field Engineering & Troubleshooting

- Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD)

- Human Vibration

- Motion Amplification Vibration Analysis

- Noise Troubleshooting

- Performance Assessment (Thermodynamic)

- PostPro – field data processing and analysis

- Structural Vibration Troubleshooting

- Thermal Striping

- Troubleshooting, Root Cause Analysis (RCA)

- Veridian iDAC

- Vibration Inspection Program

Flow-Induced Turbulence (FIT) Analysis

for High Kinetic Energy Flow

FIT analysis applies to rotating pumps (or compressors) to determine if low-frequency vibration will cause piping vibration. This study can be conducted on a standalone basis, and it is also part of Wood’s comprehensive Piping Vibration Assessment (per Energy Institute Guideline – see link below).

1 Background

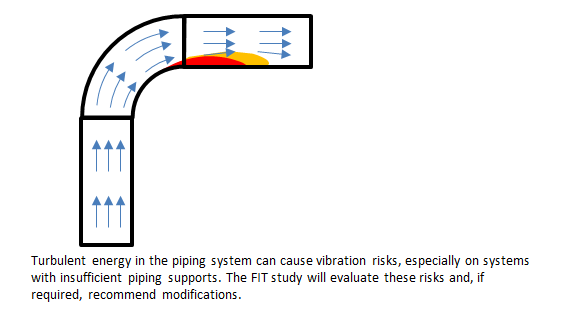

Turbulent energy is created in piping systems when fluid flows past significant flow discontinuities in the system.Typical examples are process equipment, partially closed valves, short radius or mitered bends, tees or reducers. The majority of the turbulent energy concentrates at low frequency (typically below 100 Hz). The level of excitation is higher at lower frequencies.

A FIT analysis is recommended for high flow systems with flexible and infrequent supports. One quick way to judge the risk of piping vibration related to FIT is to evaluate fluid kinetic energy:

|

Fluid Kinetic energy = pv^2 where |

risk of fit-related piping vibration |

|---|---|

| < 5000 kg/m-s^2 | Low |

| < 20,000 kg/m-s^2 | Medium |

| => 20,000 kg/m-s^2 | High |

2 Scope

The methodology used for this study is the Energy Institute’s Guidelines for the Avoidance of Vibration Induced Fatigue Failure in Process Pipework (AVIFF)

The FIT analysis considers the interaction between turbulent energy and low-frequency piping modes and makes recommendations to increase the stiffness of the piping support structure. Other recommendations include flow smoothing and dampers/snubbers.

An advanced FIT evaluation looks at the actual natural frequency of the piping system and makes recommendations to stiffen up the system.

The FIT study is a component of Wood’s Piping Vibration and Integrity Assessment

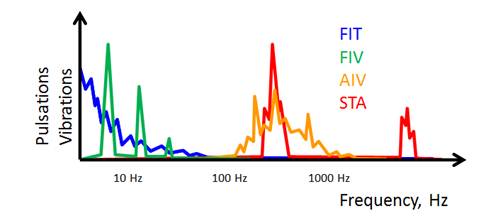

This assessment includes the excitation sources illustrated in the chart.

|

-FIT (Flow-Induced Turbulence) -FIV (Flow-Induced Vibration) -AIV (Acoustic-Induced Vibration) -STA (Shell Transverse Acoustical) |

| Excitation sources studied in Wood's Piping Vibration Assessment | |

Note that the each of these excitation sources is caused by a different phenomenon and occurs at a different frequency. For more information on the other excitation sources, refer to the related services below.

3 Related Services

- Piping Vibration and Integrity Assessment

- Flow-Induced Vibration (FIV) Analysis

- Acoustic-Induced Vibration (AIV) Analysis

- Shell Transverse Acoustical (STA) Analysis

4 Related Information

5 Keywords

- Vortex shedding

- Vortex-induced vibration

- Flow-induced pulsations

- Flow-induced excitations

- Energy Institute Guideline (2008)

- Centrifugal compressor vibration

-

Avoidance of vibration induced fatigue failure in process pipework (AVIFF)

More Info

Free webinar

Understand the top three vibration threats in your piping system and how to tame them. Register now