Services

- Static Equipment & Structures (Piping Vibration & Fatigue)

- Acoustic Fatigue Assessment for Blowdown Systems

- Acoustic-Induced Vibration (AIV) Analysis

- Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD)

- Flow-Induced Turbulence (FIT) Analysis

- Flow-Induced Vibration (FIV) Analysis

- Multiphase and Slug Flow Analysis

- Pipe Stress Analysis

- Piping Vibration and Integrity Assessment

- Review & Design Support Services

- Small-Bore Connections (SBC) Assessment

- Structural Vibration and Dynamic Design Analysis

- Subsea Piping Vibration

- Thermal Striping

- Tube Failure Analysis

- Veridian AM

- Veridian VS

- Vibration Inspection Program

- Water Hammer Analysis

- Machinery Analysis

- Bottle Sizing Service

- Compressor Package Engineering

- Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD)

- Foundation Design and Dynamic Analysis

- Fuel Gas Compressor Piping Transient Analysis

- Lateral Vibration Analysis

- Pipe Stress Analysis

- Pulsation & Mechanical Analysis: Reciprocating Compressor

- Pulsation & Mechanical Analysis: Reciprocating Pump

- Pulsation & Mechanical Analysis: Screw Compressor

- Pump RCF Analysis

- Review & Design Support Services

- Shell Transverse Acoustical (STA) Analysis

- Skid Design and Analysis

- Surge Control Design for Centrifugal Compressor Systems

- Torsional Vibration Analysis (TVA)

- Field Engineering & Troubleshooting

- Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD)

- Human Vibration

- Motion Amplification Vibration Analysis

- Noise Troubleshooting

- Performance Assessment (Thermodynamic)

- PostPro – field data processing and analysis

- Structural Vibration Troubleshooting

- Thermal Striping

- Troubleshooting, Root Cause Analysis (RCA)

- Veridian iDAC

- Vibration Inspection Program

Water Hammer Analysis

Transient Analysis for Liquid Systems

Transient events in liquid piping systems occur during normal operating activities such as valve openings/closings, valve throttling, pump starts/stops, emergency shutdowns (ESD), tank transfers, truck-out, and marine loading/offloading. These events lead to large positive or negative pressure waves that transmit through the piping system at the speed of sound of the fluid.

Transient pressures can create serious risks for piping integrity including pipe rupture, pipe collapse, cavitation, column separation, and check valve slam. These transient events are known generally as water hammer, but as this phenomenon can happen with any liquid, other terms are fluid hammer, dynamic pressure surge or hydraulic transients. This potentially dangerous phenomenon can be mitigated with good design practice and a hydraulic transient analysis (HTA).

Contents [ hide ]

1 Background

Historically, most pipeline systems are designed for expected steady state operating situations with a safety factor to cover “unexpected” scenarios. But with modern fluid modeling techniques, transients can be well understood, planned for, and designed into the piping system to improve overall pipeline integrity. Water hammer and liquid transient studies should be included in the design stage, once the initial pipe sizing, layout, and general operation of the system is understood.

Water hammer transient studies are recommended for:

- Any liquid piping system in the design stage to evaluate pipe system integrity under transient conditions

- Pipelines designed to CSA Z662 Section 4.18 and Annex M and/or ASME B31.4 Section 403.3.4

- All glass-reinforced plastic (GRP) piping where pressure transients are expected to occur, according to ISO 14692-3 Section 6.5

- Fire protection systems designed to NFPA standards where there is a significant risk of water hammer

- Predicting water hammer in pump systems for regular operating and upset scenarios (eg, loss of power)

- Predicting transients due to valve swings, sudden valve openings, new streams coming online, or other operating changes

- Pump system upgrades to flow and available head

- Systems with high consequence of failure, such as hazardous fluids, safety, environmental

- Calculating resultant transient forces on pipes to determine stress levels

- Any existing system where high vibration or shocks are occurring with valve closures or pump shutdowns

2 Scope

- Understand the operating scenarios that could possibly occur to create transients in the system

- Model the hydraulic system using dynamic fluid modelling software. The calculations solve one-dimensional governing equations of momentum and mass flow for fluids in time-domain by the method of characteristics. Calculations of velocity and pressure versus time are performed with specified boundary conditions such as given pressure or velocity versus time, open end, closed end, anechoic end, etc. Results from simulations are given as time domain or frequency domain results.

- Assess the magnitude of transient pressures in the piping system due to these system transient events

- Evaluate the effectiveness of existing pressure control and overpressure protection over a range of typical transient scenarios

- Recommend additional system protection where applicable, whether from control system parameters, specific components (valve types, locations, etc.), specific components to handle pressure surges (surge tanks, pressure relief systems, etc.), or by pipe specification or layout changes.

- Where needed, calculate unbalanced shaking forces in the piping for different operating transients

Options:

- Calculation of pipe stress due to transient forces caused by water hammer

- For existing systems subjected to water hammer events, calculation of fatigue life of piping due to transient forces

- Field testing with sophisticated pulsation and vibration measurement equipment

3 Types of systems

- Water distribution, including municipal water and wastewater, hydraulic fracking water distribution, and irrigation systems

- Fire water and cooling

- Fire protection, investigate the potentially damaging effects of the sudden response nature of fire protection systems. These include all water sprinkler systems designed under NFPA 13, and especially systems that do not feature a pump ramp up function.

- Crude oil and natural gas liquids pipelines

- Produced liquids and chemicals

- Any liquid handling systems

4 Benefits

Ensuring your piping system is safe from damaging hydraulic transient events with a hydraulic transient analysis (HTA) has the following benefits:

|

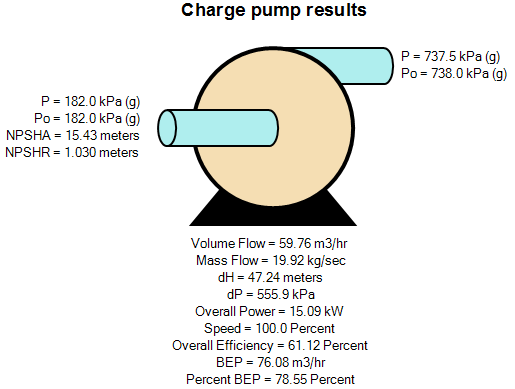

| Verification of pump operating points |

- Knowing the risk of every day hazardous operations

- Ensuring the system can handle upset conditions and transient events without failure

- Improved reliability, availability, efficiency and safety by avoiding piping, vessel failures, and fluid release

- Reduced maintenance and operating costs

- Cost-effective solutions to avoid water hammer related problems and minimize risk

- Verifification of system hydraulics including pump operating points, detailed flow and pressure predictions, and control valve operation

5 Wood advantages

Wood is a global leader in water hammer and pulsation analysis because of these factors:

- World leading fluid acoustical modeling expertise around the globe

- Responsive application advice and ongoing customer service

- Most advanced acoustical/mechanical modeling software on the market

- Timely, practical, and cost effective recommendations

6 Related information

- Video: Water hammer in piping system

- Case Study: Using Flow Element Transients to Simulate Complex Pipeline Interactions (PDF)

7 Related services

- Fuel Gas Compressor Piping Transient Analysis

- Piping Vibration and Integrity Assessment

- Pipe Stress Analysis

|

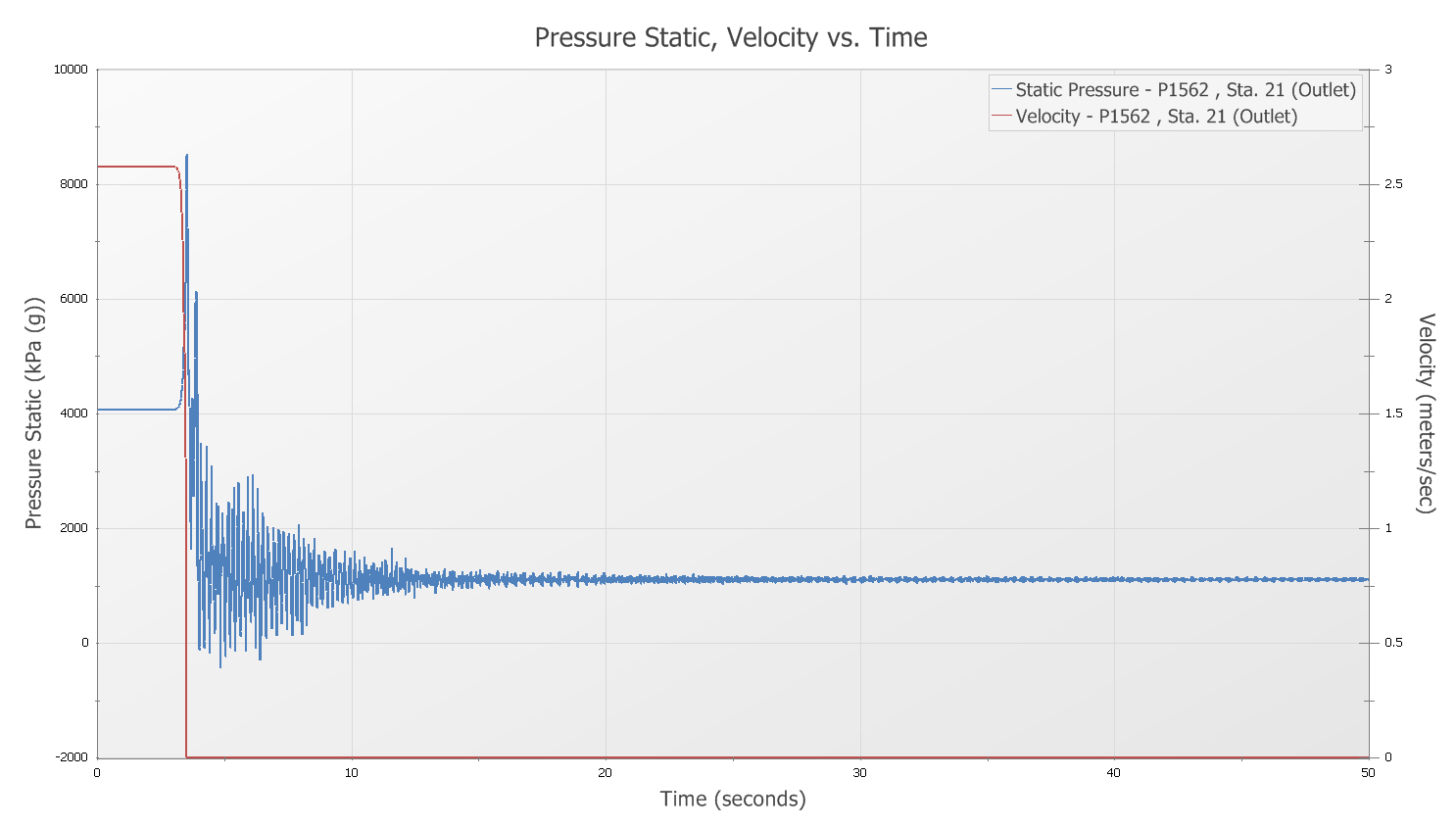

| Predicted transient water hammer events exceeding piping rated pressure |

8 Keywords

- Fluid hammer

- Surge

- Water hammer

- Hydraulic transient analysis (HTA)

- Transient

- CSA Z662 Annex M

- CSA Z662 4.18

- ASME B31.4 403.3.4

- ISO 14692-3 6.5

- NFPA

- Protection of liquid pipelines

- Overpressure protection

More Info

Webinar: Downstream performance optimization • Multi-channel vibration measurements • Webinar: Pump it up, damp it down • Vibration-induced fatigue management (Offshore Magazine) • Webinar: Shake, rattle and grow I (2022 update) • Avoiding vibration-induced fatigue failure • Pump Vibration Examples (Video) • Pulsations in Suction Piping (Reciprocating Pump) (Video) • Liquid Pumping Systems (Including Liquid Pipelines) • Structural Vibration and Ways to Avoid It • Tips for Managing a Successful Vibration Project • Example: Offshore Pump Package (Video) • Structural Vibration from Compressor (Example) (Video) •

Free webinar

Understand the top three vibration threats in your piping system and how to tame them. Register now